|

Working Principle

The energy-saving plywood dryer operates based on the reverse Carnot cycle principle and heat pump dehumidification technology. Its core function is to recycle waste heat generated during the drying process, enabling cyclic energy utilization. The working process consists of four main stages:

1. Heat Absorption Process: The refrigerant absorbs low-temperature heat from the humid exhaust air discharged from the drying chamber in the evaporator, evaporating into a low-temperature, low-pressure gas.

2. Compression Process: The low-temperature, low-pressure gas is compressed by the compressor into a high-temperature, high-pressure gas, with a significant temperature increase.

3. Heat Release Process: The high-temperature, high-pressure gas releases heat in the condenser, heating the cold air entering the drying chamber, and itself condenses into a high-pressure liquid.

4. Throttling Process: The high-pressure liquid is throttled through the expansion valve, reducing pressure and temperature, turning back into a low-temperature, low-pressure liquid before re-entering the evaporator to start a new cycle.

Through this closed-loop system, heat is continuously circulated and upgraded within the system instead of being directly discharged, drastically reducing the need for supplemental new heat.

|

Main Components of plywood dryer

A plywood dryer is a complex system comprising multiple key components that work together to ensure efficient and uniform veneer drying. Below is a detailed introduction to its main components and their functions:

1. Heating System

Heating Unit: Provides the heat source. Common types include:

Steam Heat Exchanger: Uses steam from a boiler to heat air.

Gas Burner: Directly burns natural gas or LPG to produce hot air.

Electric Heater: Heats air via resistance wires (higher energy consumption, suitable for small equipment).

Heat Pump System (Energy-saving type): Uses a compressor cycle to absorb environmental heat, with a COP of 3.0-4.0.

Hot Air Circulation Fan: Typically high-pressure centrifugal fans force hot air into the drying chamber for even distribution.

2. Drying Chamber

Insulated Enclosure:

Outer shell made of galvanized steel or stainless steel; inner lining of corrosion-resistant aluminum or stainless steel.

Insulation layer filled with 150-200mm thick rock wool or polyurethane foam, reducing heat loss by over 40%.

Air Distribution System:

Air distribution plates or guide vanes ensure wind speed deviation within ±0.5m/s.

Some equipment features adjustable guide vanes for different veneer specifications.

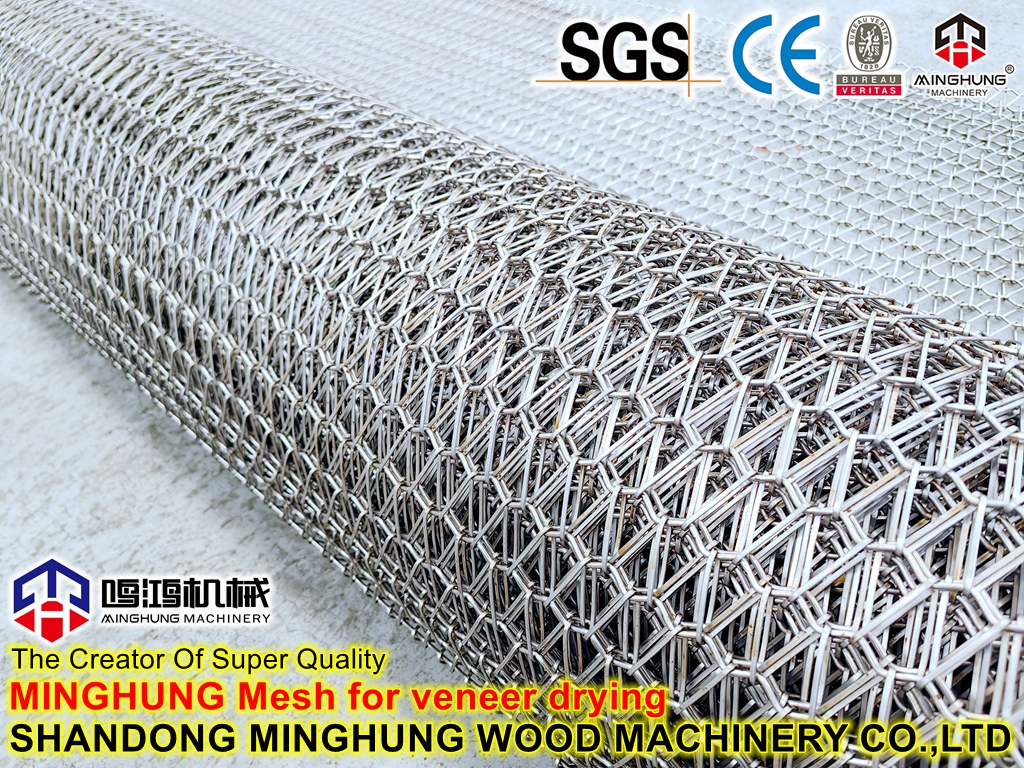

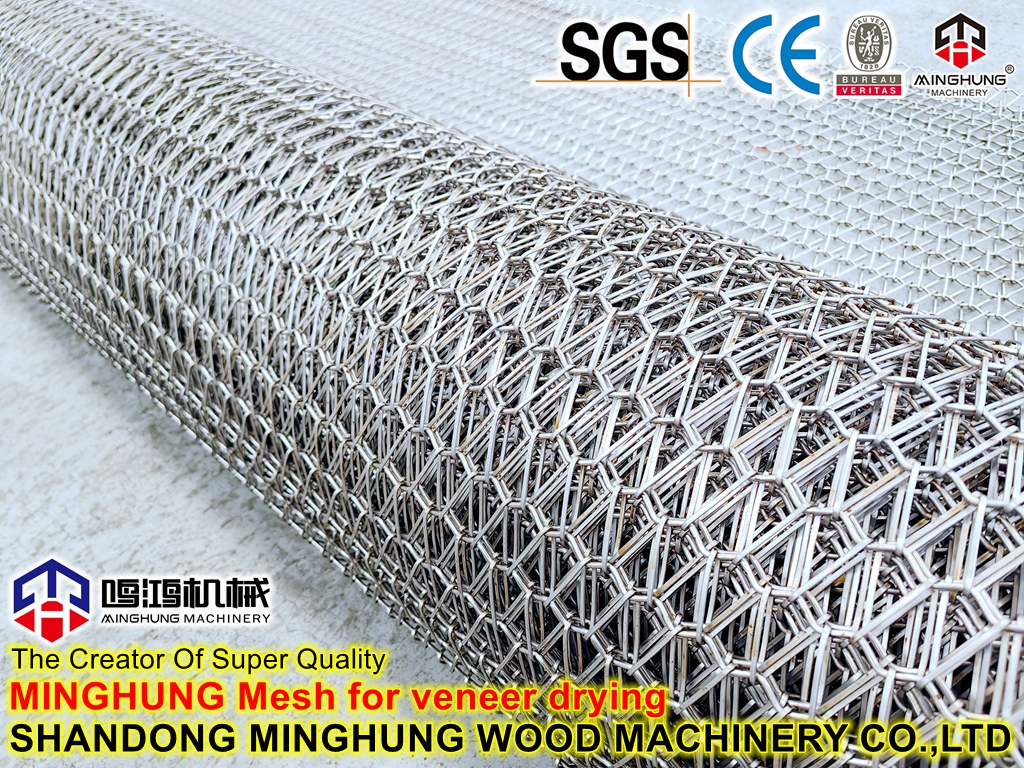

3. Conveyor System

Mesh Belt Conveyor:

High-temperature-resistant stainless steel mesh belt (typically SS304 or SS316).

Adjustable speed range: 0.5-5m/min with frequency conversion control.

Roller Conveyor (for thick boards):

Surface covered with heat-resistant rubber to prevent veneer surface damage.

4. Ventilation & Circulation System

Centrifugal Fans:

Airflow capacity: 200,000-500,000 m³/h; power range: 7.5-55kW.

Energy-saving models use EC fans, reducing power consumption by 30%.

Duct Structure:

Optimized volute ducts minimize airflow resistance.

Some equipment features alternating top/bottom airflow modes for improved drying uniformity.

5. Dehumidification System

Exhaust Fans: Made of high-temperature-resistant, anti-corrosion materials; adjustable exhaust capacity: 10%-100%.

Intelligent Dampers: Automatically adjust opening based on humidity sensor data to ensure efficiency.

6. Control System

PLC Controller: Brands like Siemens/Mitsubishi; supports multi-stage drying curve presets.

Sensors:

PT100 temperature probes (±0.5℃ accuracy); capacitive humidity sensors (±2%RH accuracy).

Online moisture detectors (infrared or RF technology).

HMI (Human-Machine Interface): 10-inch touchscreen displaying real-time temperature, humidity, and energy consumption data.

7. Heat Recovery System

Heat Pipe Exchanger: Recovers waste heat from exhaust air; efficiency up to 60-70%.

Plate Heat Exchanger: Used in steam-based systems to recover condensate heat.

8. Safety System

Fire Protection: Spark detectors + high-pressure water mist fire suppression.

Overheat Protection: Automatically cuts off heat source upon temperature exceedance.

Motor Overload Protection: All fans and conveyor motors equipped with thermal relay protection.

9. Auxiliary Components

Dust Cleaning System: Automatic pulse dust removal maintains heat exchanger efficiency.

Lubrication System: Centralized automatic lubrication for sprockets and bearings.

10.Other parts

|

Energy saving manifestations

1. Exceptional Energy Efficiency (COP):

Traditional electric heating drying has a Coefficient of Performance (COP) ≤ 0.95 (meaning less than 1 unit of heat per 1 unit of electricity). In contrast, a heat pump dryer uses 1 unit of electricity to drive the compressor and moves 3-4 units of free heat from the exhaust air, achieving a comprehensive COP of 3.0-4.5. This means it is 300%-450% more efficient than electric heating.

2. Waste Heat Recovery, Turning Waste into Value:

Traditional dryers directly discharge humid air containing vast amounts of heat into the atmosphere, wasting energy severely. The energy-saving dryer recovers 60%-70% of the heat from the exhaust air via the evaporator and uses it to preheat incoming fresh dry air, drastically reducing the energy needed to heat new air.

3. Precise Control, Avoiding Over-Drying:

The intelligent system adjusts drying parameters in real-time based on veneer moisture content. It automatically shuts down or enters standby mode upon reaching the target moisture content, avoiding the over-drying and energy waste common in traditionally controlled equipment.

4. Reduced Heat Loss:

The thick insulation layer and high-quality sealing make the drying chamber a highly efficient insulated box. Surface heat loss is reduced by over 60% compared to ordinary equipment, ensuring all generated heat is used for drying veneer, not lost to the workshop environment.

5. Efficient Operation Under Partial Load:

Utilizes inverter compressors and EC inverter fans to automatically reduce operating frequency during the later stages of drying or for small batch production, providing output on demand. This avoids the energy waste of "using a sledgehammer to crack a nut".

Summary: The energy savings of the energy-saving dryer are not achieved through a single technology, but through a combination of heat pump principle (open source), waste heat recovery (throttling), precise control (optimization), and reduced losses (insulation). This multi-faceted approach maximizes energy utilization efficiency at every stage, achieving a comprehensive energy saving rate of 40%-65%.

|

Core energy-saving technologies

1. High Temperature Heat Pump System

Uses imported compressors with heating efficiency COP value up to 4.0+

Operating temperature range -20℃ to 55℃, adaptable to different climate conditions

Saves over 65% energy compared to electric heating drying

2. Intelligent Waste Heat Recovery System

Multi-layer heat exchanger design with heat recovery efficiency over 70%

Recycled dehumidification heat reduces new energy consumption

Intelligent air damper control adjusts fresh air and return air ratio on demand

3. Precision Control System

PLC+touch screen intelligent control, real-time energy consumption monitoring

Self-adaptive drying curve adjustment avoids energy waste

Remote monitoring function supports mobile APP operation

|

Technical Parameters

Drying temperature: 40-75℃ adjustable

Installed power: Reduced by over 50% compared to traditional equipment

Drying cycle: 4-8 hours (depending on thickness)

Moisture content control accuracy: ±1.5%

Daily processing capacity: 5-20 m³ (customizable)

|

Equipment structural features

1. Insulation System

150mm polyurethane foam insulation layer

Double sealing structure reduces heat loss by 60%

Stainless steel inner tank, corrosion-resistant with long service life

2. Air Circulation System

Low-power EC fans save over 30% energy

Three-dimensional air circulation duct ensures uniform air distribution

Anti-clogging filter screen for easy maintenance

3. Dehumidification System

Frequency conversion dehumidification technology, dehumidifies on demand

Automatic dust cleaning function maintains efficient heat exchange

|

Company introduction

We are Shandong MINGHUNG Wood Based Panel Machinery Co.,Ltd China factory and manufacturer of full sets of Plywood machinery and Veneer machinery. With many years production experience, advanced production technology,experienced workers and professional engineers, we can offer you the suitable, good and strong machinery for you.

Machines include:Veneer production line(Log debaker,Veneer peeling machine, Log loader,Automatic stacker),Blade sharpener,Veneer patching machine,Veneer dryer machine(Veneer roller dryer, Veneer mesh dryer, Veneer press dryer), Veneer gluing machine,Plywood lay-up machine, Veneer jointing machine, Plywood cold press, Hot press machine,Plywood edge trimming cutting machine, Sanding and calibrating machine, Plywood overturn machine, Lift table, and so on.